Treatment of 1,4-dioxane and Emerging Contaminants:

Achieving Drinking Water Goals

In 2012, the Environmental Protection Agency released Unregulated Contaminant Monitoring Rule 3, which listed several contaminants that were to be monitored. Among the list was 1,4-dioxane, a probable human carcinogen that cannot be treated by conventional treatment systems. Though this contaminant is widely spread across the Nation, the most concentrated detections were found across Long Island, New York. H2M began to study effective and efficient solutions for the removal of 1,4-dioxane to assist our clients in protecting their public health and providing safe drinking water.

↓

It Begins Here

Episode 1

H2M’S Approach to Emerging Contaminants

Episode 2

A Conversation with the New York State Drinking Water Council

Episode 3

Piloting Our Way to the Future

Episode 4

Thinking Inside the Box

Where Do We Go From Here?

The Pilot Studies

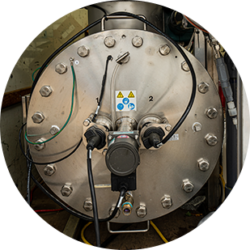

H2M tested various Advanced Oxidation Process (AOP) treatment technologies across an array of groundwaters throughout Long Island, New York as part of our pilot program in anticipation of impending regulation schedule. H2M studied four different AOP technologies in their capacity to treat 1,4-dioxane and settled on one technology that was feasible for Long Island groundwater – Low Pressure UV light utilizing hydrogen peroxide oxidant (LP UV/H2O2).

At the conclusion of this study, H2M determined the specific water qualities that impact AOP treatment and deployed these four treatment technologies in time to meet a new imposed drinking water standard for 1,4-dioxane.

Rapid Deployment of AOP Wellhead Treatment

With no EPA Maximum Contaminant Level (MCL) set, New York State announced in 2017, it would establish contaminant specific MCLs in the State for 1,4-dioxane (and other perfluorinated compounds). The Governor’s office created a Drinking Water Council (DWQC) comprised of experts and stakeholders from across the State, to evaluate issues and offer recommendations to the NYSDOH. In December 2018, the DWQC recommended an MCL of 1.0 micrograms per liter (Mg/L) for 1,4-dioxane and 10.0 nano grams per liter (ng/L) each for PFOA and PFOS.

With no clear timeline provided for implementation of the new MCL, water purveyors were faced with making critical timing decisions in the context of operational impacts to their specific systems. Faced with a compressed schedule before the MCL became effective, and nearly two dozen emergency treatment systems needed in over 12-18 months, it was apparent that a typical design/construction plan would not work. Some water suppliers with wells that exceeded MCLs risked losing the ability to meet their peak demands. Others faced being forced to remove the majority of their wells from service, potentially risking the ability to provide even average daily demand requirements.

H2M derived and innovative and effective solution by creating an AOP “box” system. Working with our clients, vendors, and contractors, H2M developed a design and construction approach for an AOP treatment that condensed construction period from 18 months to six months.

H2M’s Emerging Contaminants Leadership Team

James J. Roberts, P.E.

Senior Vice President

Market Director of Water and Wastewater

866.970.6535 ext.1017

jroberts@h2m.com

James L. Neri, P.E.

Senior Vice President

Discipline Director of Water Resources

866.970.6535 ext.1486

jneri@h2m.com